An innovative and sustainable solution for herb / Fruit / vegetable/ drying & freezing

Plastic Drying Tray, the ultimate solution for preserving the freshness and flavor of herbs, fruits, and vegetables during the drying and freezing process. Designed with precision and innovation, BYPC trays are specially crafted to cater to the diverse needs of herb, fruit, and vegetable enthusiasts, making it an essential addition to any kitchen or food processing facility.

Whether it is IQF Freezer, Freezer room, food dehydrator and dryer, you can get the ideal tray from us.

IQF Freezer (Individual quick freezing)

IQF is a freezing methods used in the food processing industry. The system is equipped with

Food-grade perforated plastic tray bottoms. The food is in individual pieces, and is frozen quickly. Products commonly frozen with IQF technologies are typically smaller pieces of food, and can include berries, fruits and vegetables both diced or sliced, seafood such as shrimp and small fish, meat, poultry, pasta, cheese and grains. BYPC trays meets these requirements, improve output, between 2 and 10 tons per hour,High yield (no damage or clustering of products),Uniform freezing of each piece of product.

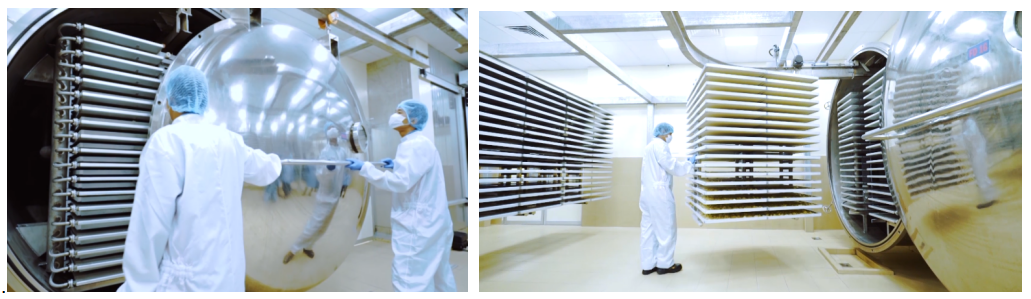

Freeze Dryer(freeze drying, lyophilisation, cryodesiccation)

Freeze drying will first freeze the food, and then reduce the surrounding pressure, causing the frozen ice in the food to directly sublime and change from solid to gaseous state. BYPC trays match drying process preserving the product's shape, color, taste, and nutrients. Freeze dryers equipped trays are perfect for processing batches for many industries ,including pharmaceuticals, pet food, CBD/hemp/cannabis, cosmetics, food processing and more.

Freezer room

Normally , used for fruit preservation, which can reduce the incidence of pathogens and rot rate of fruits through low temperature, and slow down the metabolic process of Vegetables, so as to prevent decay and prolong storage.

The choice of temperature should be paid great attention to when fruit and vegetable are kept fresh in cold storage. Different fruits and vegetables are stored different temperature .BYPC trays have wide range temperature tolerance. -40°C to 120°C. Any material of trays can be customized according to customer needs. Adjustable legs will provide more air flow when the product is thicker.

Food dehydrator and dryer

The purpose of the dryer is to improve drying efficiency, and the drying efficiency also has a lot to do with the trays.

BYPC trays meet the size of most dryers on the Chinese market. We are also constantly developing new molds to support foreign dryers.

BYPC trays made of high-quality PE or PP, it has strong load-bearing capacity and is durable. The holes in the bottom of the tray allow more airflow, increase drying efficiency. The four sides of the tray are thickened, making the tray durable and not easily deformed. BYPC plastic trays can be used below 120 degrees. Its price is cheaper than stainless steel trays. With different hole size, can meet different products. Easy to clean with high-pressure water, built to last.

BYPC has been continuously developing new trays for different industry applications. We provide custom services based on your needs.

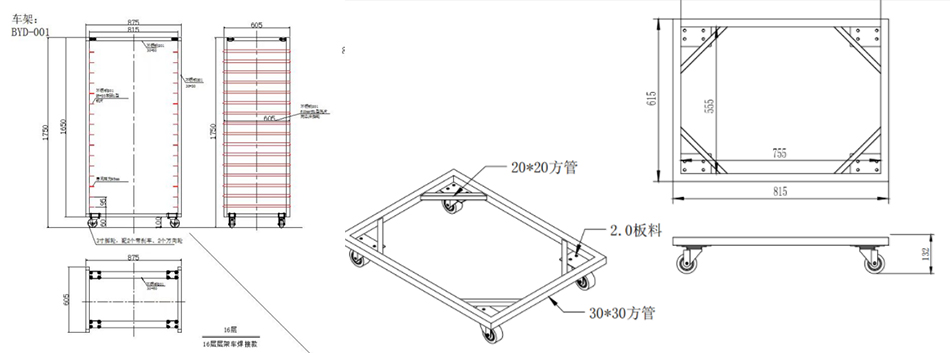

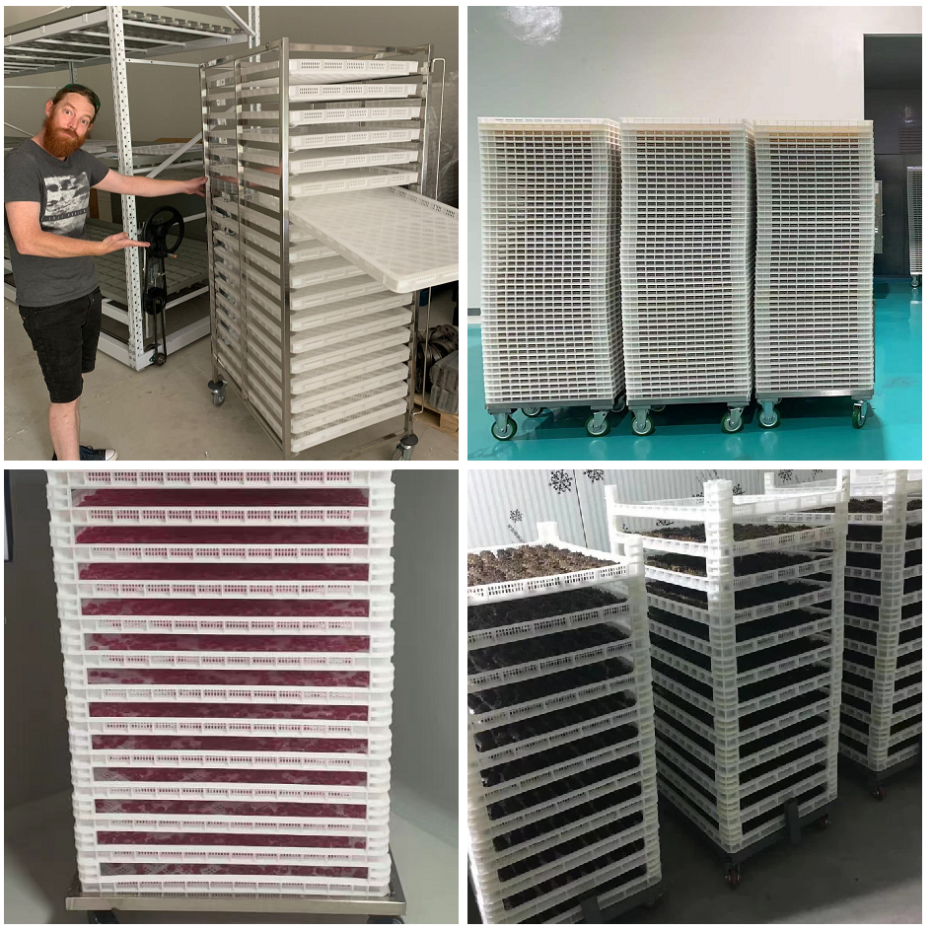

Support matching cart customization services

1. Matching carts customized based on the sizes and the structure of the trays

2. Matching carts customized based on customers' requirements on the loading bearing, budget etc.

3. various materials with different cost can be selected ( 304 stainless steel, 201 stainless steel, Aluminum alloy, plastics materials for choosing)

Customer cases drawing of the carts